رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

In high-energy ball milling, vacuum or a specific gaseous atmosphere is maintained inside the chamber. High-energy mills are classified into attrition ball mills, planetary ball mills,

Read More

2021.1.1 The aim of this paper is to use a high-energy ball mill to convert micro-sized Au powder into nano-structured Au powder; it means Au (Gold) NanoParticles (AuNPs)

Read More

2023.4.23 July 2009 . Farit Urakaev. We will focus on the important aspect of mechanochemical processing by grinding in a ball mill, namely, nanoscale wear of the treated minerals and of the milling tools ...

Read More

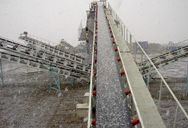

Ball mills are the most common grinding machine employed in the mining industry. Grinding occurs in a single stage, or multiple stages. Multiple stages may include a rod mill followed by a ball mill (two stage circuit), or

Read More

2017.2.13 Ball Mills. In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush

Read More

2021.10.21 Abstract. The economic and technical values of the hydrometallurgical or leaching processing are a function of its reaction rates and these reaction rates are

Read More

2023.4.30 Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze,

Read More

2016.1.1 1. Introduction The concept of a generic flow sheet for the processing of gold ores may seem to have been superseded, given the foregoing discussion of many

Read More

2017.10.1 Grace Ofori-Sarpong. PDF The comminution and leaching unit operations play a vital role in the extraction process of valuable minerals from ores. Historical research... Find, read and cite all ...

Read More

2020.3.10 Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a

Read More

Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp

Read More

2022.11.30 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis.

Read More

2016.1.1 Hydrocyclones demonstrate a trait that is useful for gold mills—minerals with higher specific gravities have a progressively finer cut-size (whether this is desired or not). In plants with free-milling gold, this leads to gold concentrating in the milling circuits (see Figure 17.13). On a size-by-size basis, concentrations of up to 100 times ...

Read More

2021.2.19 The high-grade silica was milled in planetary ball mill and the selected samples were passed through washing, crushing, dehydrating, meshing and drying operations. ... that have the same response value are connected to produce contour lines.It also shows how the SN ratio changes as a function of milling selected parameters. Fig.

Read More

2016.1.10 6”) steel balls added to the mill (hence the name of semi autogenous milling). The steel balls can occupy from 10 percent to 18 percent of the mill capacity. Given the size and form of the mill, these balls are sent into free fall as the mill rotates, providing a combined crushing and grinding effect on the ore. One of the main reasons for

Read More

2022.9.16 This review is focused on the topical developments in the synthesis of nanocomposites using the simplest top-down approach, mechanochemical milling, and the related aspects of the interfacial interactions. Milling constraints include time duration of milling, ball size, the ball-to-sample content proportion, rotation speed, and energy that

Read More

2017.9.7 Some other key drivers in flowsheet selection at the hashing stage are: Supergene weathering. This is common in tropical environments (e.g. West Africa) and typically oxidises gold-bearing sulphides down to 50-100m, transforming commonly refractory gold in sulphides to ‘free-milling’ gold, behaving in a similar fashion to gold

Read More

2020.6.1 Stirred media mills are used by the mining industry for ultrafine grinding to enhance liberation, and to decrease particle sizes of industrial minerals to tailor functional properties. This review describes stirred media mill technologies and operating principles, and summarises stress intensity theory which can be used for selecting efficient

Read More

2012.6.1 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

Read More

where d b.max is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the mill

Read More

HIGHLIGHTS OF AGICO GOLD BALL MILL. The grinding fineness and grinding time can be adjusted automatically. The cylinder body is welded by steel plates with a thickness of 15-36mm. Grease is used for main bearing lubrication to avoid heavy metal pollution. The gold ball mill has the advantages of small vibration, low noise, and low labor intensity.

Read More

2021.10.12 In high-energy ball mills, milling balls are often made of the same material as the milling chamber in order to reduce the contamination level arising from the wear of the chamber and balls 61.

Read More

2019.12.15 AngloGold Ashanti’s Tropicana Project commissioned in 2013 treats 5.8 Mtpa of moderately hard free-milling gold ore. The comminution circuit is identical to that of Boddington, with HPGRs utilized as tertiary crushers to produce a P80 2-mm ball-mill feed. ... Since hydrocyclone separation is a function of both size and density, a sharp size ...

Read More

55 known as the distribution function [45, 46]) describes the distribution of fragment sizes obtained after a breakage of particles of size xj.Thus, b1j, b2j, , bnj are the mass fractions of particles in size classes 1, 2, , n after a breakage of particles in size class j. The mechanism of breakage is illustrated in [23] by a diagram shown in Fig. 3.

Read More

2023.8.15 Comparative high pressure grinding rolls (HPGR) and cone crusher pilot-scale tests were conducted using Upper Group 2 (UG2) platinum-bearing ore in order to determine the impact of micro-cracks in HPGR products toward energy requirements in ball mills and the degree of liberation. The ball mill was fed with HPGR and cone crusher

Read More

2021.1.1 The ball milling process took a total of 20 h to complete. First I have taken initial sample 0 h. after every 4 h of milling time period i.e., 4, 8, 12, 16 and 20 h have been calculated, all the values best fit with the previous researcher values. The HWFM and integrated intensities of Bragg reflections are used to measure strain and B value.

Read More

2023.10.27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the

Read More

2018.12.17 to the environment during the milling process of ball mills. The aims of this work are: 1. To characterize the heat generation during the fracture of tantalum ore through thermography images taken after breakage by direct impact. 2. To develop a numerical model to predict the heat losses to the environment during the grinding of a

Read More

2016.10.20 How Important is the Length of the Grinding Mill to Comminution . The relationship of mill diameter to length is of considerable importance. Rod mills should have a length greater than the diameter to avoid entanglement of rods. The construction of ball mills is different in that the diameter may be larger, equal to, or smaller than the length.

Read More

2022.9.27 球磨,英文ball-milling,是一种主要以球为介质,利用撞击、挤压、摩擦方式来实现物料粉碎的一种研磨方式。 在球磨的过程中,被赋予动能的研磨球会在密封的容器内进行高速运动,进而对物料进行碰

Read More

2022.11.19 The five processing parameters (inputs) and the three quality responses (outputs) of the target mill are summarized in Table 1.Al 2 O 3 powders (AES-11, purity of 99.9%, d 50 = 0.7 μm, d 90 = 1.96 μm, Sumitomo Chemical, Japan) were used as starting powders. The value of d 50 (y 1), and the values of width and skewness (y 2 and y 3)

Read More

2020.1.16 [Show full abstract] (SAG) mill and a ball mill. Currently, the grinding circuits are inefficient in achieving the aspired product fineness of x P 80 = 125 μm even at low to normal throughputs ...

Read More

2016.3.18 The savings made in lower operation costs and lower maintenance costs are noticeable and this saving was also made in the face of a 12.5% increase in wages made when the new plant was started. Buy a Gold Processing Plant. Many of our so-called small gold mines or low grade deposits could well take this simple and inexpensive

Read More

2017.10.25 Ball Mill Breakage Efficiency. Consider a ball mill circuit processing material of a given feed size and at a given throughput rate to a target product size, the latter which once again distinguishes the “fines” from the “coarse” material. The production rate of fines or new product size material can be calculated from the circuit feed ...

Read More

1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill is used to grind the pieces of raw material into. powder-like structures. 3.

Read More

2017.2.8 The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between

Read More

The history and necessity of mechanical alloying. M. Sherif El-Eskandarany, in Mechanical Alloying (Second Edition), 2015. 2.5.1.5 Planetary ball mills. The Planetary ball mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Figure 1.1. In this type of mill, the milling media have

Read More

The breakage and liberation of minerals are the key to fluidized mining for minerals. In the ball milling process, steel balls function as not only a grinding action implementer but also energy carrier to determine the breakage behavior of ores and the production capacity of the mill. When ground products present a much coarse or much fine particle size distribution,

Read More

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG ...

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.