رسالة على الانترنت

رسالة على الانترنت

المزيد من المعلومات

المزيد من المعلومات

2023.4.26 Process flow diagram for limestone processing operations. Processing commences with transportation of the (raw) stone from the quarry to the processing

Read More

2022.5.22 By stirred ball grinding of 20 min, the m edian particle size of the limestone products. was 1.76 µm. The specific energy value was determined from the stirred ball

Read More

Context 1. ... production. As shown in Fig. 4, the following data and related inputs used for the production of crushed limestone rock were collected: explosives (i.e. ammonium nitrate fuel oil ...

Read More

2015.9.1 2-2 General process flow diagram for the manufacturing and processing of lime ..... 2-3 2-3 Preheater rotary kiln system for lime production ..... 2-5 2-4 Vertical kiln

Read More

2017.7.1 Experimentation plan: (a) flow diagram of our investigation; (b) view of the Hicom 15 high—energy mill for limestone micronization. The device used for the grinding

Read More

2022.5.22 Research results summarized primary energies, material and energy resources, emissions into different media, and eleven environmental potentials (eight most important impact categories) for wet

Read More

2017.8.26 The limestone quarry production scheduling problem can be defined as specifying the sequence in which ‘blocks’ should be removed from the quarry in order to

Read More

2021.6.25 Limestone is charged flow. Each shaft includes a heating zone, a connected in the middle to allow gas flow between downward through the heated charge

Read More

2022.10.1 The flow diagram in Fig. 4 was obtained by re-adapting the design in [74] to a PFRK calcination unit. Download : Download high-res image (467KB) Download :

Read More

2022.7.4 Figure 2.1: Flow diagram of production department. Figure 2.2: A tipper feeding the limestone at the dump hopper, Shayona. Figure 2.3: Double impact rotary crusher, Shayona.

Read More

2012.8.30 Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone

Read More

2017.8.26 Abstract—A long term production planning of limestone quarry is presented to supply consistent quantity and quality of limestone to a cement plant. A case study from Indian cement industry is presented where the cement plant has a captive limestone quarry. The objectives of this study are: (a) to investigate how long the

Read More

2012.6.1 About 2% of the electricity produced in the whole world is used during the grinding process of raw materials [1]. While total electrical energy consumption for cement production is about 100 kWh/ton of cement, roughly two thirds are used for particle size reduction [2]. About 65% of the total electrical energy used in a cement plant is utilized ...

Read More

2015.8.1 The results show that approximately 2.48t, 4.69t, and 3.41t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

Read More

2022.3.22 The initial production step in portland cement manufacturing is raw materials acquisition. Calcium, the element of highest concentration in portland cement, is obtained from a variety of calcareous raw materials, including limestone, chalk, marl, seashells, aragonite, and an impure limestone known as "natural cement rock".

Read More

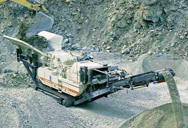

2021.9.9 Limestone Mining Process. 2021-09-09. Summary: The output of common limestone crushing sand making production line is 100-200t/h, 200-400t/h, 200-500t/h, but with the large-scale production, 800t/h, 1000t/h or even higher capacity sand making lines will become a trend.

Read More

2021.6.25 A generalized material flow diagram for a lime manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States.

Read More

2016.1.20 Considering the future growth of cement production in China, limestone deposits will be depleted in 59 years ... Fig. 10 shows the material flow diagram of the cement grinding system. Clinker (142.80 t/h), limestone (7.01 t/h) and gypsum (12.00 t/h) are classified in the V-separator with the materials returned (465.11 t/h) from the roller press ...

Read More

2019.11.13 The cement industry is one of the most intensive energy consumers in the industrial sectors. The energy consumption represents 40% to 60% of production cost. Additionally, the cement industry contributes around 5% to 8% of all man-made CO2 emissions. Physiochemical and thermochemical reactions involved in

Read More

2015.9.10 12.5.1.1 Sinter Production - The sintering process converts fine-sized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated product, sinter, of suitable size for charging into the blast furnace. The raw materials are sometimes mixed with water to provide a cohesive

Read More

2019.7.20 In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball mill in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of cement to be produced keeping the quality of cement equal or above the required standard.

Read More

2015.3.15 The sintering process is a pre-treatment step in the production of iron, where fine particles of iron ores and also secondary iron oxide wastes (collected dusts, mill scale etc.) along with fluxes (lime,

Read More

1971.8.17 The initial production step in portland cement manufacturing is raw materials acquisition. Calcium, the element of highest concentration in portland cement, is obtained from a variety of calcareous raw materials, including limestone, chalk, marl, sea shells, aragonite, and an impure limestone known as "natural cement rock".

Read More

2022.10.1 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is scarce. Subsequent hydration of lime would lead to the synthesis of slaked/hydrated lime Ca(OH) 2; the production of a tonne of Ca(OH) 2 emits ∼1.2 tonnes

Read More

2022.6.23 Through to the mixer of the selection of each component analysis and introduction, aiming at 10 in the desulfurization denitration common specifications of the limestone slurry tank, mixer technology selection on the optimization design, analyzes how to do in the desulfurization denitration limestone slurry tank mixer optimization selection,

Read More

2023.12.20 From the limestone mine, to crushing, blending, the raw mill, kiln and beyond, elemental analysis is a critical component to driving process control, efficiencies, and higher quality end products. Powerful analyzers can help you better understand the composition of your raw materials, and give you more control over downstream

Read More

2021.12.1 The gold processing industry is a large consumer of lime reagents in various forms. Its role in gold processing is mainly as a pH control agent for optimal cyanidation leaching of gold, as well as a neutralization agent in refractory gold processing via acidic oxidation routes. There are, however, a range of conditions upstream of

Read More

4 天之前 Wet Process Cement Manufacturing Process With Flow Chart. The following is a wet process of cement manufacturing step-by-step guide, 1. The raw limestone from quarries is first crushed into small size fragments. Then it is mixed with clay or shale in a ball or tube mill and ground to form a slurry of a fine consistency with the addition of water.

Read More

2016.1.20 The results show that approximately 2.48 t, 4.69 t, and 3.41 t of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages, and their waste rates are 63.31%, 74.12%, and 78.89%, respectively. The recycling rate of wastes during clinker production is remarkably higher

Read More

2 天之前 The Fig.1. show the flow diagram of the dry process of the manufacture of cement. 1. Dry Process. In the dry and semi-dry process the raw materials are crushed in a dry state. Then, they are processed in

Read More

2023.6.1 The calcination of limestone typically occurs at a temperature in the range of 800 ºC - 950 ºC [4] and is shown in Eq. 1. (1) Ca CO 3 ( s) → CaO ( s) + CO 2 ( g), ∆ h ¯ 298 K 0 = 178 kJ / mol. The energy for the lime production process is dominated by the highly endothermic reaction described above.

Read More

2022.12.21 A production flow chart is used to illustrate the manufacturing process of a product. It shows the stages, equipment used and quality control checks where you’ll check the product to ensure it meets quality expectations. If the quality is lacking or there has been any damage en route, these errors will be corrected before returning to

Read More

3 天之前 Step 1: Mining. The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded ...

Read More

Finally, during the cement grinding and distribution process, firstly the cooled clinker is ground with around 5% of gypsum and other 17 JRTE-2020 cementitious materials to form the final cement ...

Read More

1977.5.3 A generalized material flow diagram for a lime manufacturing plant is given in Figure 11.17-1. Note that some operations shown may not be performed in all plants. The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States.

Read More

2019.2.21 雅思写作小作文范文 雅思写作流程图flow chart 水泥制造过程 今天我们雅思写作大作文范文的文章来研究下流程图flow chart。该图表由两部分构成。第一张图说明了水泥的制造过程,第二张图展示了如何利用第一张图中的产品生产混凝土。老烤鸭小编搜集了一篇相关的考官范文,以供大家参考。

Read More

2020.2.3 The limestone most suitable for cement production must have some ingredients in specified quantities i.e., calcium carbonates, silica, alumina, iron, etc. Typically, cement plant locations are based upon the availability of good quality limestone in the vicinity. The quarrying operations are done by the cement producer using the open

Read More

2022.6.9 Lime is a product derived from high temperature calcination of limestone. Although limestone deposits are very common throughout Australia and deposits exist in all states, only a small portion of these deposits is pure enough for industrial and agricultural lime manufacturing. To be classified as limestone, the rock must contain at least 50 ...

Read More

2013.11.8 54,000 Btu per ton for a plant producing fine agricultural limestone as well as grade stone. The average for the 20 plants was 33,500 Btu per ton. 1 Very few studies similar to the NSA report have been generated since that time. Table 9-1. Limestone and Other Crushed Rock Production and Energy Consumed by Type a Units 1987 1992 1997

Read More

المزيد من المعلومات

المزيد من المعلومات

حقوق حقوق التأليف والنشر: رقم التدوين Development Buide 10200540 -22. خط الخدمة: 0371-86549132. E-mail:[email protected] العنوان: الرقم البريدي رقم 169 Second Avenue Avenue New Avenue: Chengzhou الصين: إحصاءات الموقع الشبكي 450001.